Conveyor systems, in addition to any other industrial management technology or inventory, have the potential to make the workplace safer and more productive. Conveyors can deliver goods, parts, and packaging quickly. However, a malfunction of the conveyor can disrupt operations, damage property, and put workers at risk. And that is why it is so important to take all necessary steps to protect yourself and to maintain or improve the efficiency of the transport system.

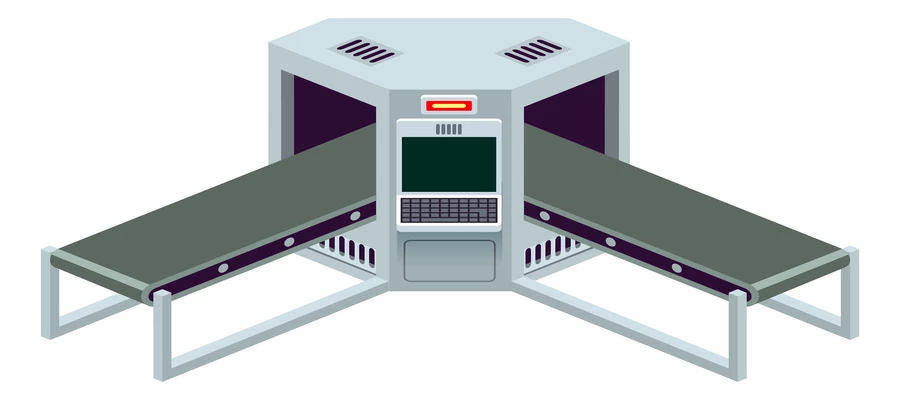

The first step is to choose the right provider for your business needs. There are many questions to consider when purchasing new transportation systems. Is the product fragile and powdery? How much moisture does it contain? Do you carry heavy loads or heavy loads? These questions will help you identify the right type of transmitter that you can choose for your process needs.

Each conveyor has its own unique set of advantages and disadvantages; therefore, you should carefully consider your options before buying. When selecting a transmitter, check product weight, speed, direction, and whether you need metal detection, measurement, or filtering. Consider system size and height for the floor area of your facility, as well as the items to be moved.

Different operating concerns will occur depending on the transport system used. A roller conveyor used to move parcels will require different care than the overhead chain conveyor used to transport a car chassis, a conveyor belt used to transport bulk paper, or a paper conveyor used to transport large quantities for sale.

Preventive care is better than effective repairs as it avoids damage to your transmitter or engine, which may cause additional problems. It also allows you to configure the system from time to time at a lower cost than waiting for it to fail and experiencing more downtime during peak times.

Every workplace should be safe. Companies are encouraged to promote a culture of safety first. This ensures the safety of employees and increases the efficiency of the company. Employees should be instructed to follow safety rules. Also, all accidents should be reported as soon as possible to management. Misuse of conveyors is not allowed. Those who abuse these unique devices must be dealt with appropriately. In addition, all staff should be properly trained to use conferences, especially in the emergency room.

A good belt conveyor can significantly improve the efficiency of the transport system because it is the only part that interacts with the pulley and products. Band style, location thickness, equipment, installation, and protocols should determine your choice. Just as you choose the right transport system, it is also important to understand the requirements of the application and the load when choosing the transport belt system for the belt conveyor of any industry you belong to.

VFD can change the sender speed to suit real-time production requirements. This helps to save energy by changing the voltage and frequency. VFD can significantly reduce power consumption by changing the speed of the car and changing the load requirements. It can also improve power features and provide soft launch power and great speed. VFDs slow down the flow of electricity, thus saving energy. For example, a motorcycle with a VFD that reduces the car's speed by 50% can save up to 90% on energy consumption. Ultimately, this can increase the life of the car and return on investment, which proves the high cost of the past.

While this is important for the food, dairy, cosmetics, and pharmaceutical industries, this type of cleaning and lubrication benefits all industries. Cleaning reduces energy consumption and friction, which can reduce the life of motors, rollers, and other moving parts.

One can rely on 13SQFT for help with all the steps mentioned in this article that can improve transportation efficiency and quality of life. It may be frustrating, but ultimately it will help reduce productivity distractions and downtime, leading to more revenue and less time spent.

POSTED BY

Ishika Adhana

Digital Marketing Executive