The vaccum dewatering (VDF) flooring method is a system for high quality laying concrete floor with optimal cost savings.

₹ 65 /sqm

Get the best quality product from verified sellers

Get pre-negotiated and highly discounted prices for your business

| Brand | Masterfloors |

|---|---|

| Anticipated Life | Same as of concrete life |

| Thickness | Customized |

| Design Type | VDF (FM FLOORING) |

| Model |

|

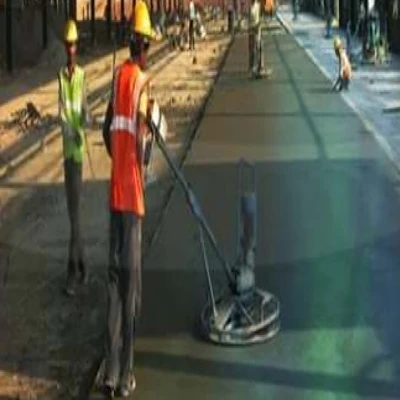

The vaccum dewatering (VDS) flooring method is a system for high quality laying of concrete floor with optimal cost effectiveness. The key to use this method is the dewatering of, by vacuum process. Surplus water is removed from concrete immediately after placing and vibrating which reduces the water cement ratio to an optimum level. Surface vibrator runs on prefixed guide channels and vibrates the concrete. Concrete surface is then skim floated by walk behind power trowel to get smooth finish, same trowel is used with blade fitted. It is most commonly used concrete floor laying technique in India. We have been providing this technique since a long time and have 15 sets of tremix flooring machines across India. We use machine with three phase power suited for small daily output @200 Sq.mtr. per day. The floor construction is in long strip of 4 meter width. Guide channel are manually fitted to require line & level.

Advantage of Vaccum Dewatering System :-

* Increases the compressive strength by 40 - 70% (higher increase is at the top surface)

* Increases Wear Resistance.

* Reduces Shrinkage of Concrete

* Strength gain in Vaccum concrete is faster than the normal way, hence earlier usability is possible.

* Surface permeability is reduced to 0 (Under Laboratory Condition)

* Reduces porosity by 20% (i.e. Dense Concrete)

* 4-meter wide strip floor construction.

₹ 76.7 (Incl. of all taxes)

₹ 65 /sqm + ₹ 11.7 GST * Freight charges will be extraQty.

To be first to post questions.

Please Login to comment