Drive-in racking is designed for the storage of homogenous products. It accommodates a large number of pallets for each SKU.

Get the best quality product from verified sellers

Get pre-negotiated and highly discounted prices for your business

| Brand | ProGulf Shelving Systems |

|---|---|

| Model |

|

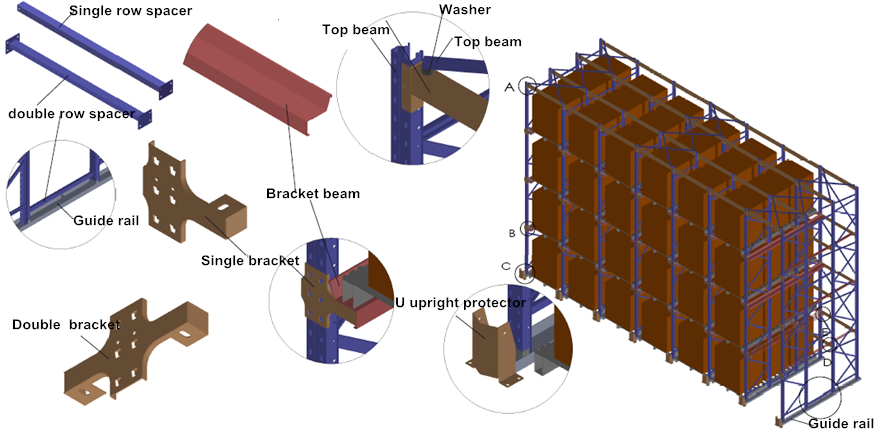

Warehouse Drive In Racking System:

Drive-in racking is designed for the storage of homogenous products. It accommodates a large number of pallets for each SKU. Drive-in/Drive-Thru Pallet Rack is ideal for stocking large quantities of relatively few items. It can reduce overall square footage requirements by 35 percent or more compared to a standard selective rack configuration.

Drive in pallet rack and drive thru racking are terms that are often used inter-changeably. It is difficult to differentiate between the two in some environments. Generally, drive-in racking requires operators to drive into the racking system from one side and remove pallets from the same entry point. Some drive-in rack systems have a wall or otherwise closed at the opposite end.

Drive-in & drive-through Racks offer the ability to store a large amount of similar product loads in a smaller area. Selectivity of product species is restricted, but storage density is outstanding. Drive in racking can store up to 75% pallets in the same space than selective racking which depends on your application. It requires fewer aisles and better cubic storage. A simple way to identify a drive-in rack systems is its LIFO inventory management. Product is rotated in a Last-In First-Out inventory manner because of the single entry/exit point.

Drive in pallet rack layout:

Drive In System Features & Advantages:

1.) Applicable to small variety but large quantity stored products, especially for standard goods;

2.) Very high utility ratio of the warehouse;

3.) Each aisle is consisted of several level of pallet support rail. Pallets are placed on pallet support rail one after another;

4.) Forklifts operate alongside the aisle;

5.) First-in-last-out access process, one side in/out or two side in/out can be met;

6.) Top and back bracing are used to fix the whole racking, making the whole racking stable and safe;

7.) First level pallets can be placed on the floor;

8.) Surface treatment: powder coated;

Please provide the following information and we will get back to you as soon as possible with a quote.

To be first to post questions.

Please Login to comment